The Best New Cruise Ships of 2023

Table Of Content

Hydrodynamic considerations also help determine the optimal positioning and number of propellers to ensure efficient propulsion and maneuverability. The interaction between the propellers and the water is carefully studied to minimize cavitation and noise, further enhancing propulsion system performance. The placement and design of appendages, such as fins, skegs, and bulbs, affect the flow of water around the hull.

Carnival Ship Rescues 27 People Adrift at Sea in the Caribbean

The immediate power delivery from gas turbines allows cruise ships to respond swiftly to changing conditions, enhancing the safety and maneuverability of the vessel. In terms of maintenance, diesel-electric propulsion systems offer advantages as well. Since the engines and generators are separate from the propellers, they can be easily accessed and serviced without the need for dry docking the entire ship. This reduces downtime and maintenance costs, ensuring that the ship remains operational and provides uninterrupted service to passengers. Azipod propulsion is a specific type of pod propulsion system developed by ABB, a leading provider of power and automation technologies. Azipods are equipped with electric motors and can be swiveled to direct thrust in any desired direction, offering superior maneuverability and control.

How Big Is a Cruise Ship Engine? - Cruise Hive

How Big Is a Cruise Ship Engine?.

Posted: Wed, 29 Jun 2022 07:00:00 GMT [source]

Practical Sample Kits by Normec MTS Allow the Crew to Take Water Samples Themselves

Of the three propulsion types presented here, diesel engines are the simplest technology. This technology is not that different from how the steamships of the 19th century. These massive vessels can consume power up to about 50,000 horsepower. Engines are designed to move large propellers or produce enough diverted electricity to drive the propellers.

With So Many Engines, Is It Possible to Experience Engine Failure?

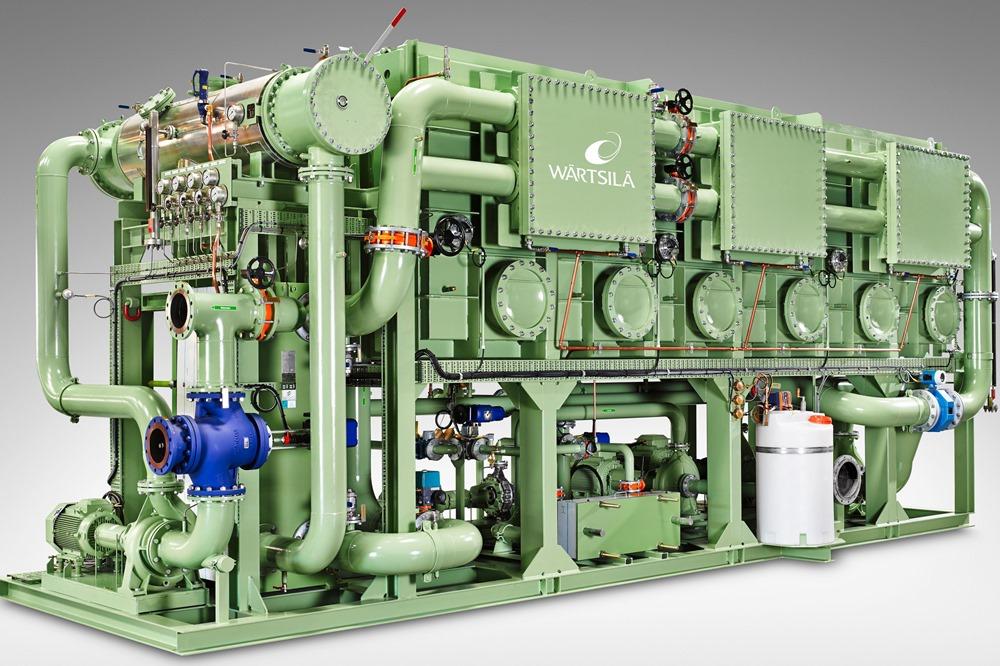

On conventional, or direct drive, diesel vessels, these engines are connected to the propeller shaft; on diesel electric ships, the main engines are connected to the main generators. Wartsila's fuel engine package was specifically designed to reduce fuel consumption. RMS Queen Mary 2's four main diesel engines are above the keel, with two smaller gas turbines on top-deck (aft of the funnel). However, current maritime legislation requires vessels to have equipment duplication and 2 engine rooms.

It has been used only since the late 2000s but is seeing promise as a more environmentally friendly method of powering cruise ships. Generally, cruise ship engines run a long time before experiencing any difficulties. Regular maintenance by the chief engineer is conducted to make sure that they are running in top condition and to prevent any mishaps while at sea. On some vessels, power for one of the fuel oil supply pumps, booster pumps and starting air compressors are also supplied from the emergency SB. The Promas Lite propulsion future clients, besides passenger ships, are marine vessels like fishing and freighter ships. In November 2013, the manufacturing giant Rolls-Royce upgraded Hurtigruten's ship MS Richard With its new "Promas Lite" propulsion system (integrated propeller-rudder system).

These factors contribute to a cleaner and more sustainable cruising experience, aligning with the industry’s commitment to reducing environmental impact. One of the main advantages of diesel-electric propulsion is its fuel efficiency. Diesel engines are known for their high efficiency in converting fuel energy into mechanical energy. By utilizing diesel engines solely for the purpose of generating electricity, cruise ships can optimize the operation of the engines and achieve better fuel consumption rates. This translates to longer cruising ranges and reduced fuel costs for the ship operators. Gas turbines work by combusting fuel and using the high-pressure hot gas to drive the turbines, which then generate power to drive the propellers.

LNG Powered Ships

The division of the engine room into separate compartments is for safety. Dividing the engine room into different containers makes it easier for the ship to contain the damage if there’s a fire or leak in the hull. Although the ship would not be able to travel at normal speed, it would be able to navigate without the assistance of tugboats. Even more groundbreaking are the designations for providing basic services -- including specifications for one workable toilet for every 50 people. Possibly the most basic detail to understand about the engine room is its location.

Engineers compensate for the noise by incorporating sound reduction technology. When it comes to cruise ships, the typical engine is a two 16-cylinder Wartsila 16V 46D which is a common rail engine. They also use three 12-cylinder Wartsila 12V 46D engines to power the ship.

Liquefied Natural Gas and New Fuel Technology

Other ships – like the Carnival Splendor of Carnival Cruise Line – may only be just four, depending on the size of the ship, its age, and the cruise line. It reduces noise and keeps the heat generated by a fully operating engine from coming out on adjacent decks. On a cruise ship, this is very important, where comfort is one of the cruise line’s top priorities. Reliability and safety play crucial roles in engine selection, ensuring continuous operation, passenger comfort, and crew safety. Cruise ship engines undergo rigorous certifications and adhere to international safety standards.

Gas turbine propulsion is a powerful and efficient system used in some modern cruise ships. This system harnesses the energy produced by gas turbines to generate thrust and propel the ship forward. Let’s take a closer look at how gas turbine propulsion works and the advantages it offers to cruise ships. This type of propulsion is very similar to traditional diesel engines. The main difference is that instead of the engine and pistons being connected directly to the crankshaft and propellers, it is connected to a generator to generate electricity. These systems utilize batteries or energy storage systems alongside combustion engines to optimize fuel consumption and reduce emissions.

As cruise ship technology continues to evolve, we can expect further advancements in propulsion systems, from more efficient and sustainable fuel sources to novel design concepts. The ongoing focus on reducing emissions, enhancing fuel efficiency, and prioritizing passenger comfort will drive the development of even more advanced and environmentally conscious propulsion technologies. In summary, thrusters are vital components of cruise ship propulsion systems, offering enhanced maneuverability, dynamic positioning, and increased safety. They enable ships to move sideways, rotate, and execute precision maneuvers in tight spaces. By providing additional power and control, thrusters reduce the reliance on tugboat assistance in certain situations and contribute to the overall safety and efficiency of cruise ship operations.

Carnival Cruise Line Cancels Two More Sailings for Ship Repair - Cruise Hive

Carnival Cruise Line Cancels Two More Sailings for Ship Repair.

Posted: Wed, 15 Nov 2023 08:00:00 GMT [source]

The engine must have the capacity to generate sufficient electricity to meet these demands. The power requirements for propulsion involve calculating the amount of power needed to move the ship through the water at the desired speed. This calculation considers factors such as the ship’s displacement, water resistance, and desired cruising speed. The engine must be able to generate sufficient thrust to propel the ship effectively and maintain the desired speeds during the voyage. In addition to steering and stability, the rudder system also plays a crucial role in emergency situations. In the event of a main propulsion system failure or loss of control, the rudder system can be used independently to navigate the ship and bring it to safety.

Comments

Post a Comment